Hydrogen in Industrial Applications

Hydrogen In Industrial Applications

Hydrogen has a long history of being utilized in a wide variety of industries, and the majority of hydrogen today is used in fields like oil refining, ammonia production, and methanol production. However, with the new need to reduce carbon emissions, hydrogen is increasingly being used in outside-the-box ways to produce both old and new products. This includes industries like steelmaking, where hydrogen is being considered as a replacement for coal and other carbon emitting fuels that are necessary for the process. Another potential new use is making concrete, which is a very carbon energy intensive process that is ripe for decarbonization via hydrogen.

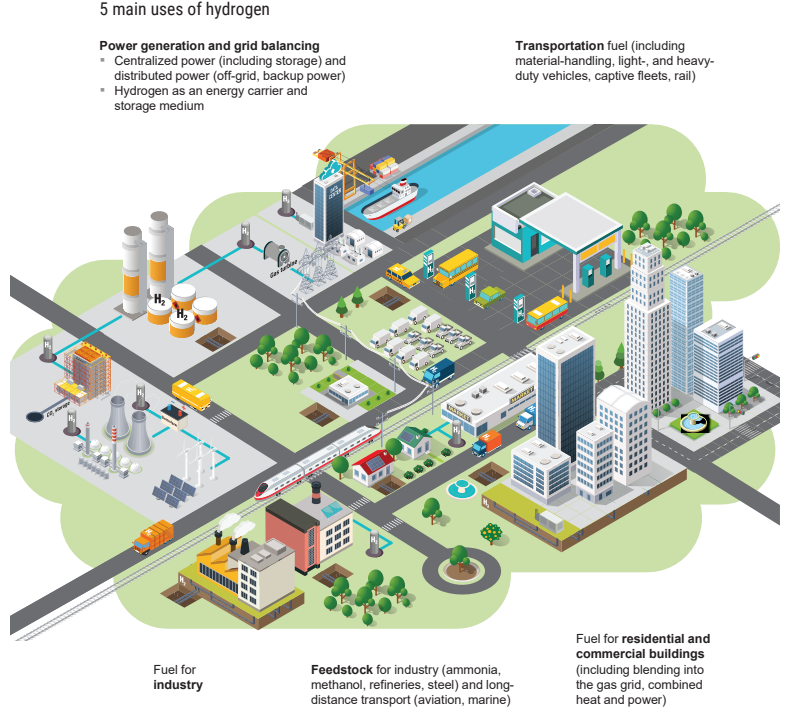

An example of what a hydrogen cycle could look like, including possible end uses. (Source: FCHEA)

Thanks to the development of the hydrogen industry in the 20th century, utilizing hydrogen in industrial practices is fairly widespread. Hydrogen is essential to the modern ammonia industry, for example, where the Haber-Bosch process combines hydrogen and nitrogen to produce ammonia. Ammonia is commonly used as a critical component of fertilizers, and as a result more than half of the world’s hydrogen production goes towards ammonia production. Methanol is another resource that is essential for many chemical products, and hydrogen is used in the refining process.

Oil refining is also heavily dependent on hydrogen for transforming crude oil into more useful fuels. Crude oil is introduced into refining facilities, and hydrogen is typically added to the mix. Refining oil requires removing sulfur in the oil until it reaches acceptable levels for the desired fuel type. Hydrogen bonds to sulfur, and creates hydrogen sulfide, which can be extracted from the fuel further along in the refining process.

A summary of the hydrogen market in the US today. (Source: FCHEA)

Hydrogen is primarily used as a component or catalyst in ammonia production, oil refining and methanol production, and these three processes currently make up the majority of uses for hydrogen production. However, as clean hydrogen becomes cheaper and the need to reduce carbon emissions becomes more important, The Road Map to a US Hydrogen Economy forecasts a hydrogen revolution, and expects that hydrogen will be used as a fuel and component for many different industries. Below is a short summary of how clean hydrogen is currently being used across the world and several exciting new fields considering the use of hydrogen in industrial processes.

Ammonia Production

Ammonia production is expected to expand by 40% over the next 30 years, and hydrogen will be a critical part of that expansion. Currently the ammonia industry is responsible for 1.8% of total carbon dioxide emissions, so there’s significant opportunity to reduce carbon emissions across the world. By using carbon capture, utilization, and storage (CCUS) and renewable energy, clean hydrogen can be substituted in the industrial process, leading to significant reduction in emissions and allowing for sustainable expansion of the petrochemical industry broadly. Ammonia also has potential as a storage medium for hydrogen, as it’s more easily transported than liquid or gas-based hydrogen. Because of this, projects producing clean ammonia have started to gain significant attention and funding.

Methanol Production

Hydrogen is utilized in methanol production, where hydrogen interacts with carbon monoxide in order to produce the chemical feedstock. By substituting clean hydrogen in the hydrogenation process, emissions can be reduced. Scientists are also looking into ways to help reduce emissions in the atmosphere via methanol production. Methanol is a viable alternative fuel for vehicles and machines, and using it can lead to higher fuel efficiency and lower emissions, in addition to the significant chemical uses.

Steelmaking

As noted in a previous FCHEA update, steelmaking is an industry that is beginning to trial using hydrogen to reduce emissions in the steel manufacturing process. Steelmaking requires a high level of heat which typically utilizes coal for both high temperatures and chemical reactions in the process. Hydrogen can be used as a substitute in this process for both the required heat and the chemical reactions. If clean hydrogen is utilized, there is widespread potential to reduce emissions, as steel is one of the fundamental building blocks of modern buildings and industrial processes.

Concrete Production

When it comes to utilizing hydrogen in concrete production, researchers are in the experimental testing stage. Hydrogen can’t be directly substituted as an ingredient or reactant in currently utilized cement production methods, so alternative approaches are needed. One approach is to use a mix of hydrogen and other inputs, such as biomass or CCUS fossil fuels in order to reduce emissions in the process. There’s several examples of this in action already, including a demonstration at Heidelberg Cement, a company which used a mix of hydrogen, biomass, and glycerin as fuel to produce the cement mix. Other companies are expected to follow, and some already have, as the incentive to reduce emissions becomes stronger.

Oil Refining

Utilizing hydrogen for oil refining is another area where clean hydrogen can reduce carbon emissions. Oil usage is essential for the world economy, and is expected to peak in demand by approximately 2040, so there is significant opportunities to reduce carbon emissions in the oil refining process. By utilizing clean hydrogen either by producing in onsite via electrolysis or producing it and shipping it after utilizing CCUS, the clean hydrogen could reduce emissions while still allowing for advanced refining.

Demand for hydrogen in oil refineries from 2008 to 2014. Utilizing clean hydrogen could lead to significant reductions in CO2 emissions. (Source: U.S. Energy Information Administration)

To learn more about how FCHEA members are utilizing hydrogen in industrial settings check out our previous blogpost on the subject here or subscribe to the Connections newsletter below.